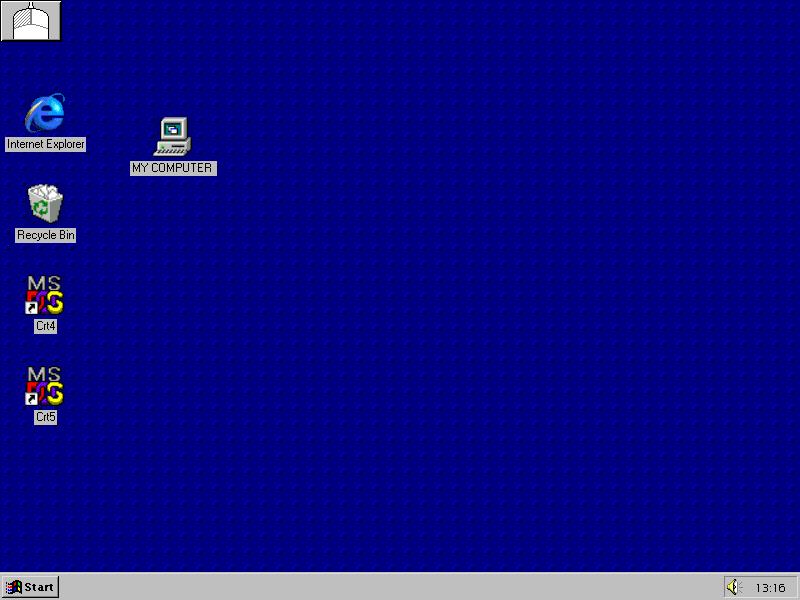

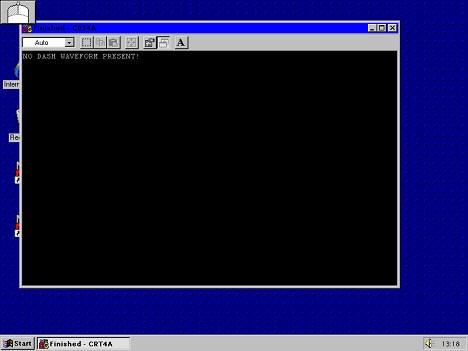

4.2

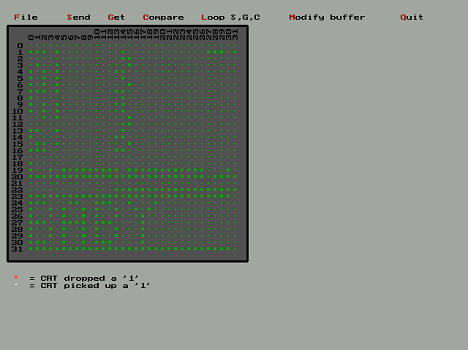

SELECT and

CLICK on "Crt4".

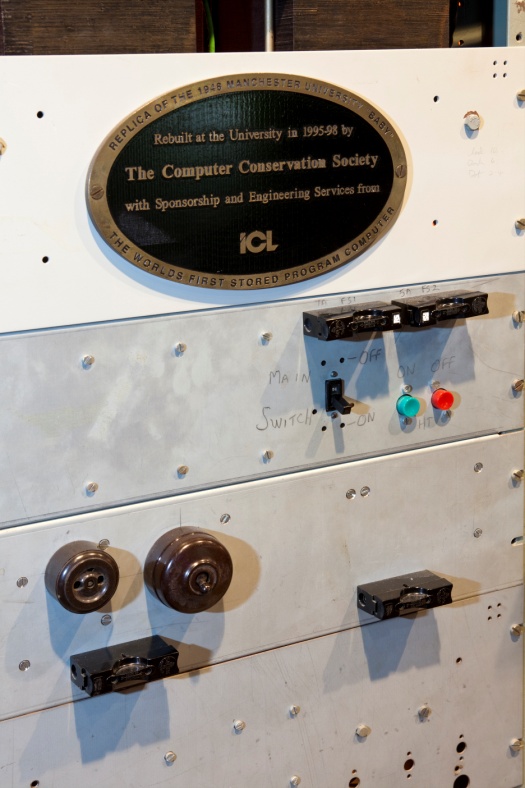

Power Control Panel

These should contain a list

of specific actions, and be periodic (e.g. hourly, daily, weekly etc.)

Ø

Use normal operation of the computer as a working check. If anything does not work normally, make a

note in the logbook, to be repaired by the ‘Baby’ technical team. Diagnostic and repair techniques are outside

the scope of this log.

7 Defect Notification

Use the operational log to

record defects/faults in the Baby computer log book and issue a report email to

the team.

If major issues arise, e.g.

smoking parts ,switch off immediately, and put a notice on the main break switch to alert

others and notify the Curator..

8 Decommissioning

Object Name: Re-built ‘Baby’

computer

Accession Number: S23/1998

Likely cut-off date: 2048 or

later

Reason for Decommissioning :

Non-availability of parts

and/or limited technological lifetime of parts

9. Type History

The World's First

Stored Program Computer,

developed at The

University of Manchester.

[This is to serve as a reminder. You should aim for delivering the history in a

maximum of 10-15 mins. You may want to

start by making a connection between the main component parts of a modern

computer and the Baby. The amount of

detail you provide will depend on your audience.]

Before the 1930s, a ‘computer’ was a person who did

calculations, whether using a pen and paper or a mechanical calculator. The person decided what calculations to carry

out and in what order.

People have used calculating machines for hundreds of

years, such as the abacus. Bank workers

at the end of the nineteenth century needed to add up large quantities of

figures and mechanical calculators were developed to meet this demand. An example is the calculator in the case by

the text panel. There are more examples

of calculating machines in the Computers Gallery in the Electricity

Gallery. In the 1930s, Alan Turing

worked on a simple, general purpose, computer.

He developed a mathematical proof that it was possible but, as no reliable

store for data or programs existed, he could not turn the idea into reality.

After the end of the Second World War, there were a

number of groups, in this country and the United States, working on an

automatic computer. One of the groups

was working at the Telecommunications Research Establishment (TRE) and included

Freddie Williams and Tom Kilburn who managed to store information on a cathode

ray tube (CRT). [Show the example of a CRT].

Williams moved to the University of Manchester and seconded Kilburn to

help him develop the design.

Williams brought in other people to help, including

Geoff Tootill. In 1947, the group

succeeded in storing 2000 bits and published a paper describing this, but was

unsure if it would work in a computer because of the speed things changed. They decided to build a small-scale

experimental machine (SSEM) and began work in 1948, completing in June. They used the computer for mathematical

problems, such as prime numbers. At this stage it was known as ‘the machine’ or

as the ‘SSEM’. Later, once there was

another computer, it was referred to as the ‘Baby’.

On June 21, at approximately 11.15 in the morning, the

program worked correctly for the first time.

It produced the right numbers and Kilburn did not believe it. He and Tootill ran the program again and the

computer produced the same answer. They

fetched Williams to show him and then went to the pub to celebrate.

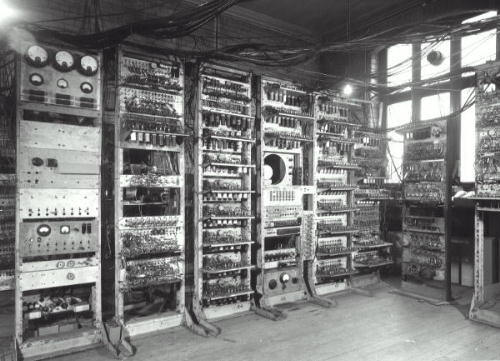

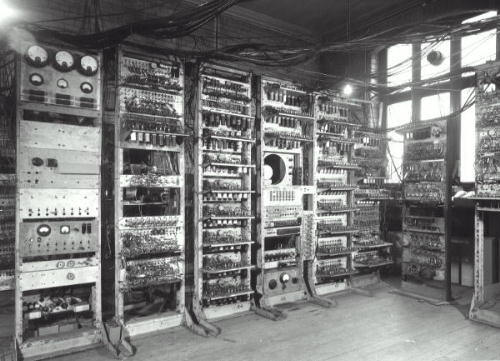

The computer you see here is a re-build of

the original which ran in June 1948.

That one was improved and enlarged into a full-sized computer, known as

the Manchester Mark I, in 1949. The

local electrical engineering company, Ferranti, re-engineered the computer and

delivered the first Ferranti Mark I to the University. The Manchester Mark I computer was scrapped

and the parts re-used.

The original ‘Baby’ from a

photograph taken of the enlarged

Manchester Mark I in December

1949

10.

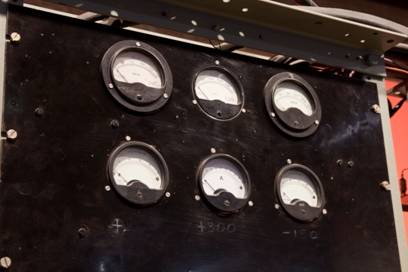

Technical Information - Digital

Storage – three cathode ray tubes

Accumulator: - accumulates the results of arithmetic

operations via the Subtractor.

- 1 word of

32 bits

Control: - 2 words of 32 bits. Controls

the extraction of instructions from the Store.

- CI (Control Instruction) - store address of Current Instruction

- PI

(Present Instruction) - buffer store for the Current Instruction.

Store: -

Holds instructions, starting values, and results, for the program.

- 32 Words 0f 32 bits (1024 bits; millions of bits

on today's chips!)

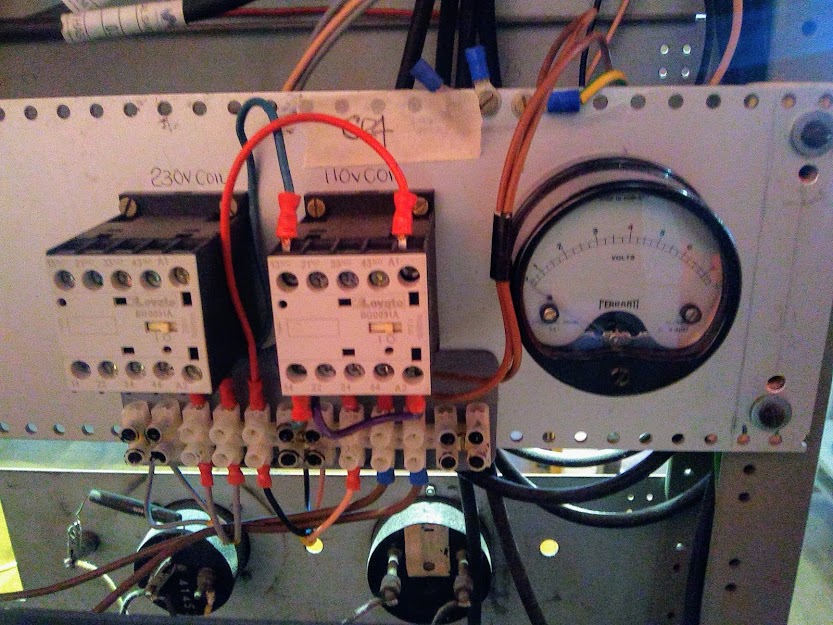

The Electronics

The team used technology developed for World War 2 radar and

communications equipment. The major components comprised 300 thermionic diodes

(EA50), 250 thermionic valves (mainly EF50 and EF55 pentodes)

Power supplies: +300V,

+200V, +50V,-150V, -1250V.

Power consumption: 3,500

Watts.

Clock Rate: 100

kHz (330 MHz in today's PCs)

Physical

Size :- 5.23m (17 ft)

long, 2.26m (7ft 4in) high Weight :-

[metric equiv.](1 ton)

Programming

There were just seven instruction types. Programs were loaded bit-by-bit

using the push-button 'typewriter'. The first program was a test for prime

numbers, and could run from seconds to hours, according to the size of the

trial number. The historic first run took just a few seconds.

11. History of

Object before entering the Museum

The Computer Conservation Society

was formed in 1989 to promote the conservation of historic computers, develop

awareness of their importance, and to encourage related research. In 1995, Chris Burton, one of the Society’s

members, drew up plans to reconstruct the original 1948 computer for the 50th

anniversary. He put together a team to

work on the project and ICL agreed to sponsor it. The Computer Science Department at the

University of Manchester also provided space for the team to work in the early

part of the project.

The team was able to identify

parts from photographs but, as the photos were taken in December 1948, they had

to extrapolate back from there to June.

They also used the few circuit diagrams, drawn by newer members of the

original team as they joined, to put together drawings and reconstruct

layouts. The team obtained the parts

from warehouses of ex-MOD material and radio amateurs. Many of the valve cartons carry dates of

manufacture [show valve 1943]. Some must

have been carried by wartime Atlantic convoys. Valves were still being made until the 1960s,

which are probably more reliable than the older valves. The post office racks came from a BT

exchange, which was closing, and from someone’s garden where they had been

holding up the lawn from the river. The

resistors and capacitors were the hardest to find and came from individuals’

personal supplies. The values of many

had changed with age. The team then

began assembling the chassis.

In 1997, the team was able to

connect up the chassis and began testing and getting the machine to work. They added three dummy stores to enable

operation of the machine without using the main store. They used a PC to load programs into the

store and for testing. The PC [round the back] has been kept to download

programs quickly but this does not affect the way the computer operates. In February 1998, ICL moved the computer to

the Museum. In June, the University, the

City Council and the Museum held celebrations and, on Sunday 21, Tom Kilburn

and Geoff Tootill ran the original program again. The University also ran a programming

competition on the Internet for people to write programs for the Baby machine

for which they had 129 entries.

This rebuild has been made as

close to the original as possible.

Indeed, Tom Kilburn has said on several occasions that he cannot find

any differences, other than that it is not dirty enough! The original was sensitive to outside

interference and certainly had problems when trams went past. In order to avoid potential problems with the

rebuild, the team put in screening. The

wiring on the rebuild is plastic, whereas that on the original was rubber. Any changes made to the original design have

been described and explained in the documentation which accompanies the project

[to be deposited at the Museum].

12. History of Object since entering the Museum

The computer was moved in to the Museum by computer

engineers from ICL in February 1998. The

re-build team then spent time in re-wiring and checking the operation of the

machine in order to ensure correct operation for the 50th

anniversary of the running of the first program on 21 June. In the event, the main store failed, but the

team were able to run the program via the dummy store which substitutes for

that CRT and amplifier. Location

references for details of modifications etc. to be collected in appropriate

formats, e.g. printed, manuscript or oral history recollections.

Since June 1998, the team has made the following

modifications:

Ø

added remote control unit behind the key switches, driven by the PC

not operable curremtly

Ø

PC used for loading programs

Ø

installed a big heaters variac to give a progressive heaters-on action

13. Additional Interpretive Information/Sources

Small Scale Experimental Machine

Volunteers -

List of Books, Audio and

Internet Resources

Books on History

*1.M Campbell-Kelly, ICL: A Business and Technical History, Oxford University Press,

1990.

Covers more than the title suggests, since ICL’s

origins lay in the punched card era.

*2.Charles & Ray Eames, A Computer Perspective: a sequence of 20th century ideas, events and

artefacts from the history of the information machine, Harvard University

Press, 1973.

Based on an exhibition assembled for IBM.

*3. J Hendry, Innovating

for Failure: government policy and the early British computer industry, MIT

Press, 1990.

Examines the role of the NRDC in the computer

industry. With Campbell-Kelly’s ICL,

this provides a definitive treatment of the early UK computer industry.

4. A Hodges, Alan

Turing, the Enigma, Burnett, 1987

An outstanding biography, particularly good on the

social and political context of the computer.

*5. S Lavington, A History of

Manchester Computers, British Computer Society, 1998.

*6. S Lavington, Early

British Computers, Manchester University Press, 1980.

Takes the story to the 1960s.

7. B Randell (ed), The

Origins of Digital Computers, Selected Papers, New York, 1973. Particularly chapter VIII on Stored Program

Electronic Computers.

*8. G Tweedale, Calculating

Machines and Computers, Shire Publications, 1990

Covers the development of calculators and computers

from earliest times to the introduction of the PC.

*9. FC Williams, T Kilburn and GC Tootill, ‘Universal

High-Speed Digital Computers, a small-scale experimental Machine', Proceedings of the IEE, 98,

part II, 1951, p13

*10.

Information File on Manchester Computing – History, stored in filing

cabinets.

Articles on Circuit Techniques

*11. BW Pollard and K Lonsdale, ‘The Construction and

Operation of the Manchester University Computer’, Proceedings of the IEE, 100,

part II, 1953, p 501

*12. FC Williams and NF Moody, ‘Ranging Circuits,

Linear Time Base Generators and Associated Circuits’, Journal of the IEE, 93, part

IIIA, 1946, p1188

*13. FC Williams and T Kilburn, ‘A Storage System for

Use with Binary Digital Computing Machines’, Proceeding of the IEE, 96,

part III, 1949, p81

The Rebuild

Project

*14. CP Burton, 'The Manchester Baby Reborn', IEE Review, May 1998, p113

CD-ROM

*15. The Computer that

Changed the World. This is suitable for a multi-media PC and includes

a simulator, a programming manual, and a

copy of S Lavington, A History of

Manchester Computers, British Computer Society, 1998.

Web Sites

Volunteers’ Website:

http://computerconservationsociety.org/ssemvolunteers/volunteers/index.html

Manchester University

(contains info on Mark I) -

http://computer50.org

Manchester University (60th

anniversary website) -

http://www.digital60.org/

Baby simulator -

http://www.cs.manchester.ac.uk/Digital60/Baby/ssem/

The National Museum

of Computing -

http://www.tnmoc.org/

Bletchley Park -

http://www.bletchleypark.org.uk/

National Archive for the

History of Computing -

http://www.chstm.manchester.ac.uk/research/nahc/

The Virtual Museum of

Computing -

ftp://ftp.comlab.ox.ac.uk/pub/Documents/museums/vlmpBAK/computing.html

14. The Museum's Staff and Volunteers' Code of Conduct states: