| Resurrection Home | Previous issue | Next issue | View Original Cover | PDF Version |

Computer

RESURRECTION

The Journal of the Computer Conservation Society

ISSN 0958-7403

|

Number 86 |

Summer 2019 |

Contents

| Society Activity | |

| News Round-up | |

| Bringing Comfort and Style to Atlas | Edd Thomas |

| English Electric and its Sucessors at Kidsgrove | John Wilcock |

| A Mystery Picture Revisited | Dik Leatherdale |

| CCS Visit to NAM-IP at Namur | Rachel Burnett |

| 50 Years Ago .... From the Pages of Computer Weekly | Brian Aldous |

| Forthcoming Events | |

| Committee of the Society | |

| Aims and Objectives |

Resurrection SubscriptionsThis edition of Resurrection is the last in the 2018-9 subscription period. BCS members and certain former BCS members (see www.computerconservationsociety.org/resurrection.htm for a detailed explanation) will continue to receive printed copies. Other CCS members may subscribe (or renew) for the 2019-20 period on the same page. |

Society Activity

|

Analytical Engine — Doron Swade The sheet-by-sheet inspection of Babbage’s vast technical archive is now in the end game after some three years. The last progress update reported that Tim Robinson, in the US, working from the digitised images of the manuscripts, was close to completing a review of the known catalogued material in the Science Museum archive and that one of the final tasks was a scrape of a relatively small but potentially critical set of drawings that had not been catalogued or scanned the contents of which are largely unknown. Tim has spent a week in London going through this material. This material evaded the Science Museum’s scanning operation in 2011 largely because it was not listed in the catalogue prepared by the late Allan Bromley who compiled the first near-comprehensive record, published in 1991, of the Babbage technical archive. There have already been significant finds. The Notations for Difference Engine 1, dating from 1834, thought to exist, had never come to light. These have now been found and represent a crucial piece in the puzzle of the developmental trajectory of the symbolic language Babbage developed as a design aid, to describe and specify his engine, and used extensively in the development of the Analytical Engine. Equally significant is the discovery of what is thought to be the legendary Plan 28a, part of the most advanced design for the Analytical Engine. There have been references to Plan 28 and Plan 28a designs peppered through the late manuscripts and some design drawings, but the existence of this plan has never been confirmed. Bromley told me in the late 1990s that he questioned whether it had existed as a separate entity in the first place in which event ‘Plan 28’ may have been a federation of improvements added to previous designs. The survey so far has identified mis-titled drawings, single drawings that have two unrelated catalogue entries, and drawings known to exist from earlier scholarly work but not located. These findings are openly shared with the Science Museum archivists in what has become a model collaboration between content specialists and archivists. |

|

ICL2966 — Delwyn Holroyd Most of the 2966 survived its long hibernation without any problems. The only casualty was the 7501 terminal, although that too has now sprung back to life before we could take any remedial action. It is of course entirely possible the fault will return in due course. |

|

EDSAC Replica — Andrew Herbert During the re-roofing of the First Generation Gallery at TNMoC the machine suffered no damage. Alex Passmore has made a number of upgrades and improvements to the power supply and power distribution. We now have an HT isolating switch on each rack to help us hunt down short circuits and two -50V DC power supplies, as required by the revised bistable design being used in critical areas. Power is also supplied to the operators’ desk. Les Ferguy and Peter Lawrence have tidied up the wiring of clock and digit pulse distribution. At the same time Les has begun labelling the ends of signal wires with unobtrusive slip on tags to deal with the problem of accidental disconnections. (In the original EDSAC wires were soldered to tag strips for security: during commissioning we have relied on mechanical fastons and these can fall off.) In addition Les has made improvements to the internal screening of the clock pulse generator chassis (and the spare) which has made it easier to set and adjust the operating frequency. Chris Burton continues the development of the clock monitor unit. Nigel Bennée took parts of the arithmetic unit home to Cambridge for upgrade and returned them to the machine. Peter Linington has continued testing the main store delay lines, driving them through the store access logic and main output bus. The main control commissioning team (James Barr, Tony Abbey and Tom Toth) have resumed their work. Having shown EDSAC cycling on executing a single X (no-op) order in location zero of store, the next step is to enable the sequence control system to allow execution from consecutive locations. The team has been having some problems with the clock and digit pulse setting. These include being able to make fine adjustments to the clock to obtain the correct delay in the main store, jitter, drift as the machine warms up, incorrect amplitude and shape of pulses. The clock pulse generator has had several improvements to deal with these issues and Chris Burton has constructed and installed the Clock Pulse Monitor chassis to enable setting to the correct frequency for the store. Issues about pulse shaping remain which may require some adjustment of how we distribute the various clock signals around the machine and further possible improvements to the clock pulse generator. |

|

SSEM — Chris Burton The Power Supply sub-system has been a little troublesome over recent months. The first issue is that the switching-on sequence relies on the operator following a defined procedure, and any deviation could result in tripping of the main circuit breaker outside the compound. It only happens rarely, but a small modification is being implemented (with curatorial permission) to reduce the risk of deviating from procedure. The second issue is that every few weeks a transient glitch on one of the power rails occurred, enough to stop a running program. This has now been tracked down to a percussion-sensitive potentiometer in one of the power modules. The same fault was noticed 14 years ago, and seemed to cure itself. But it has reappeared and appropriate action taken to fix it. Good work by the Level-4 volunteers. |

|

Our Computer Heritage — Simon Lavington Within the last few months, updates to the delivery lists of the following computers have been made: EMIDEC 1100, EMIDEC 2400, English Electric DEUCE, CTL Modular One. With the help of colleagues from the CCS-NW and from the Monash Museum of Computing History, the delivery-list of Ferranti Sirius computers is being revised. It seems that several of the Sirius machines delivered to UK customers ended their days by being passed on to Blackburn College of Technology and Design. Anyone who has first-hand experience of the Blackburn College computers, or other Sirius installations in the UK, is asked to contact Simon Lavington. |

|

IBM Museum — Peter Short Our 029 card punch has been fitted with a wooden leg. One of the back legs was damaged in transit from Oslo and the initial fix proved to be too unstable. We are now looking for a parrot to sit on top... The four punch & verifier machines on display now sit on appliance moving rollers. This means they can be easily pulled forward away from walls for access to the rear. The 029 has received a full preventive maintenance; mechanically it appears to be sound apart from one of the two drive belts that has stretched. Unfortunately we don’t have a spare but we might be OK for a while. We’ve had no success with other IBM preservation groups, however we think that a 2L23 belt is a direct equivalent. So far no replies from any belt manufacturers. There were still faults in the relay circuitry somewhere; fortunately we found wiring diagrams on line and tracing continued. We discovered that none of these diagrams directly matched our machine, so finding a short circuit became tricky. Even though we’d already cleaned the relays and timing circuit breakers, my colleague Nick gave the CBs yet another thorough clean, and the short circuit disappeared. At this point the punch clutch seized. This is a spring clutch, and the pulley had not been fully on, so a coil of the spring dropped into the gap. Punch clutch springs are not the most common item to be held onto by an ex-CE, but another colleague Peter (the other Peter) just happened to have a bag of springs, including one punch clutch spring! Phew, saved again. Whilst it now punched cards, the keyboard was extremely sluggish. A set of 44 tiny steel discs in a brass channel prevent more than one key being depressed at a time, and they had become magnetised and oily over time. They were removed, cleaned, degaussed, spilled on the carpet and 41 subsequently found. Fortunately my box of washers contained a few of these from way back when. The keyboard feels great now. Sitting next to the 029 is the 5496 from Oslo, a buffered punch & verifier for 96 column cards. We have ascertained that it does still work OK, except the motor does not stop running after a few seconds. This is probably the micro switch on the top cover, and we’ll try and sort that soon. We also need to do some revision how to create programmes – it’s been a long time! An artefact that has lain in a box in the back office for many years has finally been identified. It is a roll of clear printed litho film, with a gear wheel on one end and a small coiled spring in the other. Thanks to a couple of more detailed photos from Namur, we are now sure this is from the operator console of a S/370 Model 138, developed in Hursley. |

More Mystery PhotographsOndrej Novak (taranrazr@gmail.com) from the Czech Republic asks whether anybody can identify the ICL circuit boards at tinyurl.com/yxvmjnfr. And Peter Short at the Hursley Museum is equally mystified by www.computerconservationsociety.org/images/mystery.pdf . He thinks it might be an IBM customer engineer’s tool of some kind, or not. It has an octal valve base with three leads going to base pins, and what looks like an electric motor or gyro with two leads to base pins but nothing else externally. All help gratefully received. |

|

Elliott 903 — Terry Froggatt In the previous issue of Resurrection, I reported that the TNMoC 903 was working well, in my home, except that, occasionally, a program tape could not be loaded by Initial Instructions for the first two or three minutes from power up in the morning (at below office temperature). Due to the transient nature of the problem I’ve been unable to find the cause. On the other hand I have successfully run the 903 (warm) for 24 hours with mainly its own “M” cards and for another 24 hours with mainly the spare “N” cards. Also whilst running some tests, I discovered that the 903 would stop if I touched the front edges of the cards in slots 44 & 45 (whether “M” or “N” cards were in those slots), and I believe that this was caused by a small whisker of wire found resting on the backplane. On Saturday 30th March 2019, with the Large Systems Gallery roof completed, and with X3 function test loaded into the 903 core store at home, I set sail with the 903 to TNMoC, where I reassembled it. X3, and various other tests, all worked correctly as expected. Not wishing to push our luck, we did not reconnect the Engineers’ Display Panel or the Extra 8K Store on this visit. The bad news is that within a week or two of being returned, the 903 began to be troublesome for the first hour or so of each day. The good news is that an hour is long enough to try card swapping. By the end of April, Peter Williamson had potentially located the fault as being on A-FA bit-sliced register card N41 in slot 42, and he had replaced it by another spare A-FA, N37. It is quite likely that the TNMoC large systems gallery gets colder overnight than does my computer room. According to the installation manual, “The 900 System is designed to withstand a wide range of environmental conditions, so that reliable operation is ensured in a normal office environment of temperature range 10 to 30°C and relative humidity range 20 to 95% without condensation”. Meanwhile Peter Onion has been bringing the 803 out of hibernation. He too was having trouble with the chilly environment, which was making the core store unreliable at the start of the day. On Public Holiday Monday 22nd April, he reported that, even though all the store tests were passing, the Algol compiler would stop with a parity error at the same place in every source, with the accumulator clear except for bit 35. Adjusting, and then swapping, the read amplifier for bit 35 made no difference. When he checked the inhibit signals on bit 35 in both halves of store he noticed that bit 35 in the lower half looked shorter that the rest. So he changed the bit 35 SZ2 inhibit driver in the lower store, and the symptoms went away. After further amplifier adjustments on a subsequent visit, the 803 now appears to be OK. |

|

Harwell Dekatron/WITCH — Delwyn Holroyd The roof works over the First Generation Gallery were completed at the end of February as planned. The only issues found were some broken wires in the connectors of a couple of the rack interconnecting cables, probably caused by these fragile cables being disturbed. By the end of the day the machine was working satisfactorily. But problems soon appeared. These began as occasional hiccups before becoming more frequent. The main symptom was the machine stopping or powering up with the transfer and carry unit HT supplies turned on outside of an arithmetic operation with random trigger tubes fired – this should never happen. If it does a power cycle is required to recover. This is because a train of pulses known as returned carry B (RCB) pulses are needed to extinguish the supplies and these are suppressed if any carry trigger tubes have fired. The lack of these pulses also makes it impossible to start any new arithmetic operation. Much time was spent analysing the circuits responsible for switching the transfer and carry HT to see if anything appeared marginal, but there was nothing obvious and during an entire day of investigation the machine refused to go wrong at all, only for the problems to return the very next day when no engineers were present to witness it! Eventually however we managed to capture on ’scope what was causing the supplies to turn on at the wrong time – B pulses breaking through on the “10B” output lines. Pulses should only appear here when the Dekatron in the pulse generator spins. The breakthrough came when realising this coincided with all of the main HT supply voltages suddenly rising by 10% or more before dropping back. Now confident that we were looking at a power supply issue as the root cause it didn’t take long to trace the fault to one of the main series regulator valves (EL360) which was deciding to periodically ignore its grid input, presumably due to some kind of internal short developing. Finally it is my sad duty to report the death on 8th April of Dick Barnes at age 98. Dick, along with colleagues Ted Cooke-Yarborough and Gurney Thomas at AERE Harwell, designed the machine in 1949. Dick had been the last survivor of the trio and visited us several times during the restoration project, taking a keen interest. He was present, along with Ted Cooke-Yarborough, at the TNMoC Reboot event in 2012. The fact that the machine he co-designed is still operational today and providing education and entertainment to a whole new generation is a fine testament to his skills. |

|

Software — David Holdsworth KDF9 Programming Languages The offering of our four KDF9 programming language implementations is being sanitised so that the material all lives on the main server (sw.ccs.bcs.org) except for the on-line execution facility sw.ccs.bcs.org/KDF9/langs.htm. The representation of KDF9 Algol Basic Symbols has now been unified as in: sw.ccs.bcs.org/DAVID-H/KDF9/chars.htm Brian Wichmann’s test programme continues, and from time to time leads to the removal of errors/quirks. Attempts to use the proper library rather fell foul of the limited capabilities of our substitute Usercode compiler, and even using our modern Usercode assembler, we have discovered that a key part of the library is missing. A recent idea for combining the genuine output routines with a cut-down handling of Algol Basic Symbols has very recently been implemented, and looks good. It is incorporated into the Kidsgrove Algol on-line facility. Bill Findlay’s ee9 emulator is about to undergo a new release, and is revealing (what we already knew) that our two emulations of floating point are not exactly in line. The emulation in my own kdf9.c was always thought to be an approximation. We are actively investigating incompatibilities between the Whetstone and Kidsgrove implementation and Brian Wichmann’s data from his work with real KDF9s in the 1970s. Leo III The Leo Society and the Cambridge Computer Museum have received a Heritage Lottery Grant for the preservation of Leo artefacts. This was presented at a reunion on 7th April, where I also presented a new system that I have developed which better showcases the user interface to the LeoIII Master Routine. I am now in discussion with the HLF people at Cambridge about the prospects of our CCS endeavours having a part to play in their Leo Heritage Project. There is much activity aimed as reading over 200 Leo magnetic tapes that have “appeared” recently, most of them via eBay. Delwyn and TNMoC are much involved in the conversation, which is showing much promise at the moment. If we can read these, we have hopes of resurrecting Leo’s COBOLish language CLEO. |

|

Bombe Rebuild — John Harper We are now back to being able to provide demonstrations, with our full team of volunteers, every day of the week. TNMoC already have regular school and planned group visits and can now, if they wish, extend public opening times as they deem advisable. The machine is able to run full demonstrations but with one small lingering problem where the ‘stop’ letter does not always indicate without an additional operator action. However knowing this allows the machine to operate as it should and we could now run new jobs if required. One long term problem has now been identified. For some time we have experienced relay points burning or welding together. This is due to a high current flowing for an extended period. We have found that the way that we demonstrate, by switching off the power after a stop to explain this to visitors, puts the machine in a state when re-applying power and starting again produces this high current condition. We have no reason to believe that this situation would have been encountered by WRNS in WWII because they would have no reason to do this. To avoid this situation we have modified our demonstration procedure and as further precaution added a small filament lamp in series with the offending circuit. This limits the current to a safe level and also light up to show that any excessive current situation is present. The machine still works as it should with this lamp in circuit. As we have carried out significant repair and maintenance activity recently we have realised that we do not have all the spares that we should have to hand that we would need if the machine should break down. We made many extra spares at the time of the original build but now realise that the stock is incomplete. For example there are a pair of bevel gears in the main drive train that, if these should fail, we could have a machine that is out of action for a very long period. We are now embarking on a search for somebody to make these high risk items. |

CCS Website InformationThe Society has its own website, which is located at www.computerconservationsociety.org. It contains news items, details of forthcoming events, and also electronic copies of all past issues of Resurrection, in both HTML and PDF formats, which can be downloaded for printing. At www.computerconservationsociety.org/software/software-index.htm, can be found emulators for historic machines together with associated software and related documents all of which may be downloaded. |

|

ICT/ICL 1900 — Delwyn Holroyd, Brian Spoor, Bill Gallagher ICL 1904S/ICT 1905/ICL 1901A Emulation A few improvements to the user interface, which affects both the basic emulators and the UIs – still in test before release. PF50 (1902A etc.) Despite E3NG loading and getting into GELL (George Loader), there are still problems. However, a source of the PF50 logics and documentation has been found! A large parcel weighing some 10Kg containing some 4,000 – 5,000 pages of drawings and specifications landed on Bill’s doorstep (thanks to Jacqui at TNMoC for packing/dispatching these) and these are now being sorted, read and scanned, a process which will take some considerable time. So far no answers to current problems down in the engine room. However, these documents should answer any outstanding questions. A Christmas Challenge GEORGE 0/MicroMOP is now complete and has been successfully run on both the 1904S and 1905 emulators. We hope to test this on the TNMoC 2966 under MPOE. GEORGE 1 and 2 These were batch systems for small/medium 1900 systems, and quite probably had more users than GEORGE 3. We have issue tapes for GEORGE 1 (both variants), GEORGE 2 three3 out of the four variants) and 2+ (four versions). In addition to the binary issues we also have source for two of the G2+ versions, and derived source for the others. G2+ was still being actively developed into the 1980s, the final version G2+DOF/2B having various improvements over version 2A. We have the disc based GEORGE 2 (for which we have the manual) running quite happily alongside MAXIMOP, a useful combination probably giving better throughput than GEORGE 3 on a similar sized system. We are lacking the earlier manual that describes GEORGE 1 and the other versions of GEORGE 2, so effort is being put into looking at the binaries of the other versions to understand how to install and run them. Work has also been done on installing G2+DOF/2B – it installs but crashes, either we are missing some patches or additional installation instructions over the previous version. More work is planned in this area; we do have various manuals, but not the latest amendments. |

News Round-Up

|

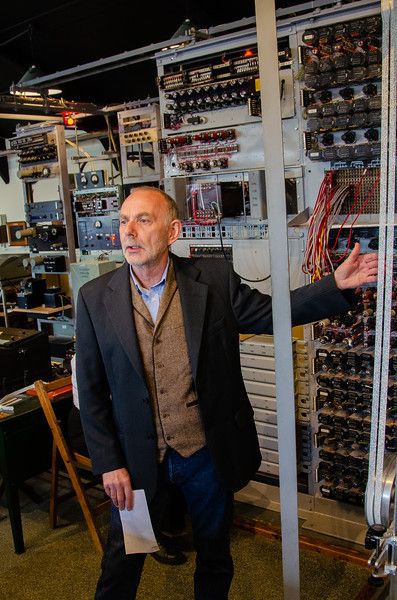

Once again a prestigious award has been presented to a CCS member. This time it’s the turn of Ben Trethowan who has been given an Individual Award for Cyber Law Enforcement in his role as a special constable for Hampshire Constabulary, where he volunteers within their Cybercrime Unit. Ben has developed solutions to analyse security monitoring data from cybercrime victims; built local and regional cyber-threat intelligence; and assisted in the automation of other intelligence tasks. Ben also assists in the investigation of active cybercrime cases, including network penetrations and denial of service attacks, within the Hampshire area. In our world Ben is best known for his leading role in the restoration of IRIS the DEC-based air traffic control system at TNMoC. So, two volunteer roles as well as a proper job. Wonderful! Well done Ben! 101010101 101010101 Our good friends in the Leo Society tell us that Frank Land has been awarded an OBE “for services to the information systems industry”. Frank sees it as “a sign of recognition of the LEO contribution to information systems”. Can’t argue with that now can we? Congratulations Frank. 101010101 101010101 Finally, despite his usual reticence, mention must be made of Doron Swade’s recent award of an Honorary BCS Fellowship. Best known perhaps for his creation of the Babbage Difference Engine, Doron was co-founder with Tony Sale of the Computer Conservation Society. Without his untiring work, none of this would have been possible. We are all in his debt. 101010101 101010101 We hear that a pair of IBM 360/20s + peripherals (and a 370/125) have been discovered in an abandoned building in Nuremburg. Offered for sale on eBay it has been acquired by three TNMoC volunteers and, by the time you read this will have been shipped to the UK. The 360/20 was the smallest machine in the 360 series having a much smaller (and slightly incompatible) instruction set compared with the rest of the range (cf. the ICT 1901) and was limited in other ways too. But it was seriously cheap resulting in more than 7000 installations in the US alone. ibms360.co.uk for more details. Interestingly, the punch card handler was sufficiently slow for the processor to decide whether to reject an incoming card to a different stacker, just like a tabulator (for which the model 20 was often a replacement). 101010101 Our ever-enthusiastic friend Herbert Bruderer asks whether anybody can locate a Roman, ivory hand abacus which seems to have disappeared from view. More information at tinyurl.com/yxhx4839. |

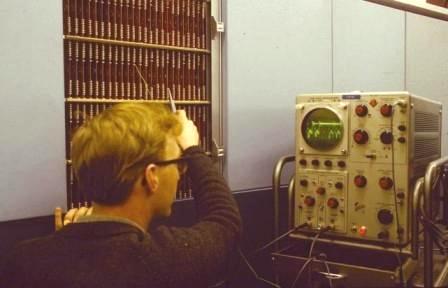

English Electric and its Sucessors at KidsgroveJohn WilcockThe English Electric Company (EE) was formed in the aftermath of the first world war by a merger of various electrical engineering companies. In 1919 it purchased the Siemens Dynamo works in Stafford from the British government which had confiscated it from its German owners during the First World War. From 1931, Stafford became the headquarters. Initially concentrating on the heavy end of the industry – generation and transmission plant, electric railway traction and so on – the company deepened and broadened its scope over the years partly by organic growth and partly through a series of acquisitions which took it into diesel engines, aircraft production, light electronics, domestic appliances and much besides. English Electric’s Kidsgrove Works A few miles to the north of Stafford a new site was created from 1952 in the Butt Lane area of Kidsgrove in Staffordshire to accommodate the expanding Industrial Electronics Department of English Electric previously located at Stafford. Butt Lane was the birthplace of Reginald Mitchell, designer of the Supermarine Swift, the forerunner of the Spitfire. Mitchell worked at railway locomotive builder Kerr Stuart, in nearby Hanley, but then spent most of his working career at Supermarine in Southampton. The new site was referred to as the Kidsgrove Works. The majority of the land was owned by Kidsgrove Urban District Council and was largely empty fields with some small farms. Between 1890 and 1934 some of the land had also been used for coal mining at the Old Butt Lane Colliery. Some industry already existed on the site, the nylon mill of G.H. Heath of Macclesfield, and the aluminium works of Thomson Brothers of Birmingham. The programme of work called for site construction huts to be erected by 25th August 1952 and excavations to start by 8th September 1952. Steelwork for the site could not be supplied without written permission from the Admiralty in London due to the Iron and Steel Regulations introduced by the Ministry of Supply. During the same period a new road was built linking Linley Road to old Butt Lane. The new road was named West Avenue and was built by the Kidsgrove Urban District Council. The whole site on West Avenue was named the Nelson Industrial Estate after George Horatio Nelson, later Lord Nelson, English Electric’s chairman and managing director, rather than the historically famous admiral killed at the Battle of Trafalgar. The first industrial building for electrical engineering on the south side of West Avenue was the Kidsgrove main engineering site of English Electric. Over the next five decades the rest of the estate evolved, making the site the biggest employer in the local area. In its heyday in the 1980s the estate employed over 4,000 people and supported many more jobs in Staffordshire as suppliers and sub-contractors. The design and manufacturing activity at Kidsgrove was quite diverse ranging from portable instruments to control gear and systems. he computer age had just begun and English Electric started to design and make the Luton Analogue Computing Engine (LACE). During the Second World War secret development work had taken place in the English Electric Guided Missiles Division at Luton on analogue computer designs. These machines were based on thermionic valve technology and were aimed a t military applications. Production of the LACE was transferred to Kidsgrove in 1954, but this development was short-lived because of the increasing dominance of digital computers. The Luton factory of English Electric was finally closed in 1962 and production was relocated to Stevenage, later to become part of ICL. The company’s interest in digital computers came through contact with the Pilot ACE group at the NPL, which included Alan Turing. Sir George Nelson was at that time a member of the NPL Executive Council. He and the company’s Research Director, J. K. Brown, quickly realised the implication of the NPL proposal to develop a computing engine. This contact was formalised in January 1949 when A.C.D. Haley was recruited to head a team of about 12 engineers and technicians on loan to NPL. The English Electric team cooperated with the NPL group to produce the Pilot ACE, which entered service in 1952. Computer design was continued by EE at the Nelson Research Laboratory on the outskirts of Stafford. This then led to the 1955 production model DEUCE, manufactured at Kidsgrove and Blackheath Lane, Stafford. First-generation computers such as DEUCE, built of thermionic valves, became obsolete within a few years. A new semiconductor device, the transistor, which replaced the function of the triode valve, was invented by Shockley in the USA in 1950. Transistors, together with other discrete components such as resistors, capacitors and diodes, were assembled on printed circuit boards to build the second generation of computers. Where was EE to get transistor knowhow? The answer was provided by Marconi at Chelmsford, then part of EE. The key point was that the Marconi personnel working in the USA and Britain still regarded themselves as working for the same (Marconi) company: transistor know-how and computer designs soon passed by agreement and licence from RCA to EE. The single transistor was replaced by the 1960s by small scale integrated circuits (SSI) with about ten components on the same 5mm square “chip” of semiconductor. Using this technology, the second-generation computer KDP10, manufactured at Kidsgrove, was a copy of an RCA design. Using the same technology the KDF9, a home-grown hardware stack-based computer which was one of the first to demonstrate multiprogramming, originated at Kidsgrove, while the KDN2 was an industrial control computer built at Chelmsford. Two parallel divisions emerged, one concentrating on industrial control applications called the Control Gear Division and the other specialising in computers called the Data Processing Division. To support these businesses the site had a range of shared services including a sheet metal shop, a machine shop, and a coil winding section making transformers and magnetic amplifiers (“magamps”). Between 1953 and 1955, with the completion of Bays 1 and 2, work on an MoD radar project, codenamed Postal, was transferred from temporary premises at a disused chapel in Thomas Street, Talke to Bay 2, and the design and manufacture of a range of RF induction and dielectric heaters with ratings up to 5Kw was transferred from Stafford to Bay 1. Several laboratories and offices were set up in each bay dealing with the development and design of electronic instrumentation equipment, peripherals for DEUCE, and magamps. Between 1954 and 1958, with the increasing need for manufacturing space, parts of the hill to the east of Bays 1 and 2 was cut away, exposing some old mine workings from the former Butt Lane Colliery, and enabling Bays 4 and 5 to be built, with a gap between the two sets of bays (sometime later Bay 3 was fitted into the gap, not without some difficulty, as the two sets of bays were not exactly parallel to each other). Bay 3 was built to accommodate a test facility for DEUCE mainframes, and special ventilation ducting was needed to deal with the several Kw of heat that each generated. About five mainframes could be accommodated at a time. During this period a section known as “Valves & Seals” was transferred from Rectifier Division, Stafford to Bay 1 and ultimately to the basement. This was a production unit only, with engineering responsibility remaining at Stafford. The “Valves” were small simple anode mercury arc rectifiers, the majority being ignitrons, whose most important use was for spot welding equipment. Much attention had to be paid to the perfection of the special “Seals” between the glass envelope and the external electrical connections. During the Second World War, the Germans had launched hundreds of V2 rockets on England. Part of the guidance and control system in V2s used the pioneering technology of “magnetic amplifiers” (magamps) for servo control of the stabilising fins. This technology was adapted and developed in the 1950s for use in control systems. Magnetic amplifiers were used for power control in a variety of system applications, predominantly in steel rolling mills and other continuous processes, controlling the fields of DC machines. The main magamp toroidally wound components used for control systems were designed as epoxy resin encapsulated units of some complexity, and considerable space was required for their manufacture. The coil-winding for these and for transformers was done in different locations over the years, with special facilities for resin encapsulation in one of the newer bays. Hundreds of magamps of this type were manufactured between 1954 and 1958. In 1957 investigation into the use of thyristors for power control commenced and it was soon apparent that thyristor amplifiers (converters) would cause the demise of magamps, depending on the development and availability of higher voltage and current capability of the thyristors. However, some of the control advantages of magamps would be lost and the control system technology would need to be modified. This was facilitated by the introduction of transistorised operational amplifiers. Major building work continued throughout the 1950s and did not finish until the end of the 1980s, the last building to be built on the Kidsgrove site being the Northfields Block in 1988. More land was acquired in 1954 including the area on the opposite side of West Avenue which became the computer factory. Also a small section of high wooded ground near what was to become the sports pavilion was bought. This land was purchased in anticipation that the firm would move into radar equipment for the control of guided missiles, and would use the land for the siting of aerials (but this never came about). In 1955 work commenced on the new Bay 3 to accommodate the expanding company. In June 1958 an order was placed with Taylor Woodrow for construction of the new canteen block. The start of the 1960s found English Electric becoming short of space and buildings. The workforce had increased from a few hundred in 1954 to 2,000 in September 1961. Thus during 1958 and 1959 a number of “temporary” wooden huts had been installed at the back of Bay 5 (these were officially called “Pratten Buildings” but were always referred to as “the huts”). Planning permission for the huts was given and was due to expire in December 1961, but in practice these temporary huts continued to be used for the next 30 years. The first huts to be built were called A, B, C and D blocks, and they housed a total of 224 people. In May 1961 the Chairman gave the go-ahead for the construction of new buildings on the north-west side of the road, to be called “Westfields”. These new buildings, comprising workshops and an office block, were to house the growing English Electric computer business. Six acres of land were purchased, and building started in July 1961, scheduled for completion by autumn 1962. The factory part was modelled on the St. Albans works of Marconi Instruments Ltd. From 1963 the new computer business existed alongside the traditional Control Gear Division of English Electric in the Kidsgrove works, with the factories on both sides of West Avenue. The business prospered to such an extent that more land and buildings were required in 1965 by which time employee numbers had risen to 2,700. In May 1966 a specification was drawn up for the construction of a four-storey office block to be located at the north-eastern end of the site. This was to become “Northfields”. Work commenced in July 1966 and was scheduled for completion in April 1967.

A second-generation computer built from transistors was required. English Electric did not have such capability at the time, but the Marconi link allowed computer designs to pass from the Radio Corporation of America (RCA) to English Electric. The first machine built, the KDP10, was a copy of the RCA 501. Kidsgrove then went on to design a new machine based on this technology, and the KDF9 was the result. The KDF9 was in production from 1963, and it was regarded as a very successful machine. The same link was exploited for the third-generation of computers, using integrated circuit technology. The English Electric Computers System 4-50 was a copy of the RCA Spectra 70/45, and was again very successful. Other models were the Kidsgrove-designed System 4-70 and 4-52, and the Chelmsford-built System 4-30 and 4-40. The 4-70 was compatible with the 4-50 (having exactly the same instruction set) , but the 4-30 regrettably had an instruction set that was incompatible with the 4-50 in a few but very important respects. To say that the 4-30 was Chelmsford “built” was an exaggeration – at first Marconi forgot to build it, and then when they finally did get around to building it the instruction timings were about 30% greater than specified, so the 4-30 was immediately cancelled, being replaced by the 4-40 model, which was a slugged (artificially slowed-down) version of the 4-50. Note that the 4-50 had already been slugged so that its performance was slower than the RCA Spectra 70/55. The store access was 16 bits wide (a halfword): the hardware procedure was to access the halfword, select one byte, then access the same halfword again and select the other byte. English Electric’s initial technology exchange agreement with RCA did not allow the 4-50 to be unslugged. However, unslugging became possible many years later for the 4-52 model, when the repetitive slugged access procedure was removed, thereby replacing eight elementary operations with five operations for each half word accessed. Some staff moved out of the Kidsgrove site in the late 1960s to offices in Copthall House, Newcastle-under-Lyme, myself included, to set up a new research department for the detection of faults, a need of the Field Engineering Division. This may seem strange, but the technique was to find a failing printed circuit board among the hundreds stacked in the large equipment cabinets of the second and third generation computers. The offending board was then replaced. Compare this with modern computers where the only board to throw away is just one – the whole computer. In the mid-1960s, English Electric had acquired the LEO Computer company and the data processing interests of Elliott Automation. Then in 1968 the data processing interests of English Electric were merged with International Computers and Tabulators (ICT) to become “International Computers Limited” (ICL). At Kidsgrove, the site was rent asunder, one side of the road being given over to ICL and the other remaining (for a short while) with English Electric. At this point we must consider the history of the two parts separately The GEC Kidsgrove Story Meanwhile, in the late 1960s the British electrical industry underwen t a revolution as GEC acquired Associated Electrical Industries (AEI) in 1967 (which encompassed Metropolitan-Vickers, British Thomson-Houston (BTH), Edison Swan, Siemens Brothers and Hotpoint). Then later in 1968 GEC merged with English Electric (incorporating Elliott Brothers, the Marconi Company, Ruston and Hornsby, Stephenson, Hawthorn & Vulcan Foundry, Willans and Robinson and Dick Kerr). The era of English Electric was unfortunately over, and the new era of GEC began. Sir Arnold Weinstock was Managing Director and Lord Nelson was Chairman. The new company was called GEC-Elliott Automation Ltd and Kidsgrove was first called English Electric-AEI Industrial Controls, then GEC Elliott Industrial Controls and finally GEC Industrial Controls. Thus the English Electric name was lost. English Electric had lasted 49 years (1919 – 1968) and the GEC era lasted for 21 years (1968 – 1989). For more details see Anatomy of a Merger by Jones & Merriot 1970 . GEC Kidsgrove came very close to closure in 1969/70 as GEC wanted to move everything to Rugby. Only the strong arguments of George Spratt (Head of EE AIC) kept Kidsgrove open. In December 1984 the company set up the Hybrid Circuits manufacturing plant (at the back of the canteen block). This facility produced miniature circuit modules to be used on a variety of drives and PLC boards. The area used the concept of clean rooms, and operators wore full overalls, hats, etc. to exclude dust. 1984 also saw the first real progress with the new surface-mount technology that is now standard for PCBs. 1989 marked the start of the biggest series of changes to affect the site since 1968. It was announced that a new company Cegelec would be formed which was jointly owned by GEC (22%) and the large French company CGE (78%). Cegelec had 27,000 employees world-wide. In December 1989 a new Managing Director John Seed took over at Kidsgrove from Don Prowse and he began adapting the company to suit its new Anglo-French ownership. Whereas the 1980s had been boom years for the company, the 1990s were a period of downsizing with devastating effects on the workforce. The UK had started a recession and major companies like steel, mining and the car industry were hitting hard times and not spending. The company’s order book fell severely and in May 1990 many redundancies were announced, including senior management, as the company re-structured to survive the coming years with a much-reduced business level. In 1992 the situation had not improved and at the start of the year a further 90 redundancies were announced. As sales continued to fall it became clear that the company could not afford to employ the workforce it still had. Around March 1992 massive job losses were announced effecting all areas of the business. In the second half of 1992 another major change was announced. The Low Voltage Control Gear Division and SCP were transferred to GEC-Alsthom which had recently been established. Only 320 people were retained. By 1993 the total Kidsgrove workforce had been reduced to around 700 people, less than half the workforce of 1989. The reduced numbers on site meant that rationalisation of buildings was needed in order to cut costs. By January of 1993 Northfields office block was finally emptied having been in use for 27 years. Likewise, the old huts were emptied and the original huts A, B, C and D were finally demolished. The key words of the decade were retention of core activities and everything that was not core was to be purchased outside. Traditional production and quality methods were scrutinised and changed. Full 100% inspection of components was replaced by “green route” initiatives where the supplier did the checking. Independent inspection was replaced by self-inspection. By 1999 Cegelec had become part of ALSTOM, a new company listed on the stock market that included most of the old Cegelec companies and many of the GEC-Alsthom companies.

On a national level in 2002 the financial news of the time carried tales of the final downfall of the Marconi Company. Marconi had changed its name from GEC and had seen its shares fall from more than £12 to 2p. The once mighty companies English Electric and GEC had virtually been destroyed. It is somewhat ironic that the same year saw the death of Lord Weinstock who had been at the helm of GEC from the 1960s. He was gone, and so was the empire he had built up. He must be turning in his grave. What had happened in simple terms was that in the 1990s GEC had sold off all of its heavy engineering capability (transport, power, transmission, etc.) to ALSTOM. This left it only with telecommunications, which then proceeded to hit a severe recession, from which the company could not recover. This was a sad decline for the old Nelson Industrial Estate at Kidsgrove. The last staff left in 2004 and the site was demolished.

The ICL Kidsgrove Story ICL had inherited a diverse range of incompatible computers from its constituents. At a stroke, it announced that it was discontinuing many of these models, and would not be maintaining them further. The System 4 range continued for a while but was not promoted with much energy. In 1974 the ICL 2900 Series of computers was launched. For nearly 20 years its flagship VME operating system was developed on the Kidsgrove site before being transferred to Manchester. In addition, firmware was used to emulate the most popular inherited computers, the ICT 1900 Series and the English Electric Computers System 4-50, within the new 2900 computers. Component manufacture continued at Kidsgrove, but the move to ever more complex integrated circuits saw a decline in assembly work for new computers and the site started to become a sub-contract electronics manufacturer alongside its traditional role within ICL. Readers may recall the short-lived boom in Hoover washing machine and vacuum cleaner sales when that company offered free flights to the USA for anybody spending more than £100 on their products. This generated so much demand that Hoover was unable to cope. Bizarrely some of the resulting sub-contract work was done by ICL at Kidsgrove.

The company prospered due to the boom in mobile phones and communications equipment and had a workforce of more than 2,000. A manufacturing service “badge engineering” (sub-contracting of clients’ products under the clients’ own badges) became the norm. The Nokia contract was big business. There were two large assembly lines making PCs for Dell. Fibre optic products for ICL continued, and there was work for SUN, IBM and defence contracts. Novelties were the gyro system for the Segway personal transporter (scooter), the pca for supermarket card readers, and the Camelot lottery terminals. Kidsgrove became the “board-stuffing” plant, with assembly going to Ashton-under-Lyne and Czechoslovakia. ICL’s need for manufacturing facilities continued to decline and in 1997 ICL, shortly before its full absorption into Fujitsu, sold its entire manufacturing operation to Celestica, itself a spinoff company from IBM. The Kidsgrove site was used by Celestica for the manufacture of printed circuit boards and assemblies to the design of many different computer manufacturers. This new prosperity was not to last however, and the former ICL plant closed completely in 2007, a very sad decline for what had been an important employer in the area. The legacy of the English Electric Computers made at Kidsgrove was:

After graduating from the University of Oxford, John Wilcock joined English Electric in 1961 at Kidsgrove, where after a graduate apprenticeship he became a KDF9 computer engineer (an abiding memory of the night shift was hearing by radio that J.F. Kennedy had been assassinated). After programming DEUCE, and doing research work in fault finding in the Diagnostic Programming Group of Field Engineering Division, he left ICL to join academia. He retired as Reader in Computing of Staffordshire University in 1997. Contact at jdwaw@btinternet.com. Some additional material by [ed]. |

A Mystery Picture Revisited

Dik Leatherdale

In Resurrection 83 I published a photo of a card reader and asked whether anybody could identify it and in particular, its host. Chris Burton identified it as an ICT 593 card reader. Martin Wright and Tony Yule both suggested that it might be connected to an ICT 1301 computer. Certainly, all 1301s had a model 593, but built into the long operators’ console. Moreover, the photo we showed exhibited different panelling to that shown on available 1301 photos. We know that the 593 was available within early ICT 1900s, but again, lodged within a larger housing. The Ferranti Atlas and Orion computers also had 593s available which would have been free-standing as per our original photo. Perhaps there were other possible hosts. So, we’re not really much further forward. Or are we? Peter Wooledge made contact with a very interesting piece of information. He’d looked closely at the accompanying half punched card (something I’d never done) and found the text “D MEREDEW LTD”. Now it turns out that Meredew was a manufacturer of furniture based in, of all places, Letchworth – quite near the ICT factory there. So, the supposition that my father had fitted the shelf himself is probably wrong. More likely it came from the manufacturer using a piece of plywood which had outlived its usefulness as an ICT exhibition display board and did further duty as packaging for a delivery to a nearby ICT customer. Meredew fell on hard times in the 1970s and was taken over, closing altogether in 1990. www.vintageretro.co.uk/?s=meredew is a useful reference for those interested. My thanks to all who have helped. |

CCS Visit to NAM-IP at Namur

Rachel Burnett

Our annual CCS excursion took us this spring to the computer museum in Namur www.nam-ip.be. The visit itself was on Saturday morning, and so we all took the opportunity to spend the weekend in Namur, the capital city of the Wallonia region of Belgium, a picturesque old town, with its historic medieval citadel and several small, interesting museums. It is easy to reach by train via Brussels and Eurostar. The Computer Museum was certainly well worth visiting. It is excellently presented, and it is hard to realise that it was founded less than three years ago, for preserving equipment and materials representing the development of computing in Belgium, in the context of the human and social environment in which the technologies were developed. The four sections at the core of the museum are: Bull; Burroughs/Unisys; the Scripture collection; calculating machines. We also viewed a temporary exhibition Odinateurs des Sixties, for which IBM Hursley Museum Services had provided scanned photos and some technical information. We were privileged to look round the reserves, where sea containers used for transporting some of the equipment to the museum have imaginatively and practically been re-used for storage. The Bull collection dates from 1920. One of many highlights in this section is the working 1960s punched card equipment – the Museum has a big supply of cards! Burroughs, founded in 1886, was a major manufacturer, first of calculators and then computers. A hundred years later, Unisys was formed by the merger of Burroughs and Sperry. Notable items on display include the first printer calculator invented by William Seward Burroughs in 1886; the first portable calculator dating from the 1920s; the Moon Hopkins 1921 – the first accounting and invoicing machine using direct multiplication; and a rare example of a 1950s magnetic drum from an early Univac solid state computer running at 17,000 rpm which is filled with helium to cool it. The Scripture Collection consists of material demonstrating the different stages of the project pioneered by the Abbey of Maredsous, using computers to develop a multi-lingual biblical database and analyses of Bible texts in Hebrew, Greek, Latin, French and English, from its inception in the 1970s until its completion in 2010. The resulting Concordia Polyglotta is an index to the Bible. In the early days of the project the monks transferred information from the Bible to punched cards and travelled to Brussels to run them on National Savings Bank computers at night. The display of calculating machines features numerous models demonstrating the evolution of different kinds of machines for calculating: abacuses, slide rules, mechanical and electro-mechanical calculating machines; electronic calculators, and those with display units; from micro-computers to office PCs and laptops, up to the present day.

The Museum houses an original Hollerith machine from the 1880s, one of just four still in existence worldwide. It has been classed by the Wallonian Government as a ‘Masterpiece’, which means that it cannot be moved out of the country, and only skilled workers may maintain it. Herman Hollerith worked for the US Census Bureau, and designed this first punched-card tabulating machine for the 1890 US census. He leased the machines to the Census Bureau, taking out his own patents, and leased the machines internationally. He was the inventor of punched cards for recording, storing and processing information, and chose their size to be the same as the US$100 bill, so that they could be stored in the same cases used to store the bills. IBM brought this Hollerith machine over in 1958 for the Brussels World’s Fair. The machine came to this Museum after having been left in the metallurgy museum in Liège (originally computer workers in Belgium were classified as metallurgy workers).

Of course these particular examples singled out from all that we saw are but a few of the many remarkable items on display. We are very grateful indeed to Frère Ferdinand Poswick, General Manager of the Museum, who had organised the arrangements for our visit to the Museum and in relation to our time in Namur itself; to Ward Desmet, the Chairman of the NAM-IP Association and our outstanding guide round the Museum; and to Carine Mahy, Gaëlle De Cupere and Yolande Juste. Those of us who had arrived in Namur by Friday afternoon were warmly welcomed formally by NEW (Namur-Europe-Wallonie), the association for promoting Namur. This was followed by a visit facilitated by NEW to the Musée des Arts Anciens du Namurois, which has some very beautiful pieces of art from the region. This museum houses the superb Treasure of Oignies silverware from the 13th century, with its exceptional quality and craftsmanship. It also displays a fine collection of paintings by Herri met de Bles, a 16th century Flemish Northern Renaissance landscape painter. This was the CCS’s fifth visit to a computer museum abroad. When we arrange next year’s visit, details will be advised to members and posted to the website. If you would be interested in joining us, you will be very welcome. |

50 Years ago .... From the Pages of Computer WeeklyBrian AldousCGranada’s Honeywell Hardware: Aiming at a dual-purpose system which will provide real time support for TV spot advertising and cope with a massive batch processing job, Granada Group Ltd installed a Honeywell H2200 computer in Bedford last September. Now Honeywell has delivered further hardware in the form of 10 Cossor visual display units and three Data Dynamics teletype units. These are being systems-tested in Bedford and will subsequently be installed in London to be linked to the computer over two 1,200 baud GPO telephone lines. (CW142 p8) 360/44 Aids Research into Earthquakes: Earthquakes occur regularly inside the IBM computer at the New Mexico Institute of Mining and Technology. Only simulated ones, but they are reproductions of real earthquakes which are recorded almost daily at or near the institute. A 360/44 is being used by a special research team which is attempting to find out more about the origin and nature of earthquakes. Problems to be solved include: how portions of the earth slide and what triggers the activity; how earthquake waves travel through the layers of the earth; what happens to the energy, and what are the directions of earth movement during a ’quake. (CW142 p9) Sadie and Susie firm goes Public: Following the successful launching of Kode International as a public company last month, Business Computers Ltd is now making a similar move and lists opened today (Thursday) for the sale of 700,000 2s Ordinary shares at 21s each. The company, which makes and markets the Sadie and Susie invoicing and stock control computers, took on its present form in August last year when Business Mechanisation Ltd, the marketing end of the organisation, took over Systemation Ltd, the company which makes the machines at Portslade, Sussex. (CW142 p20) 1905E to go On-Line to Wards in Hospital: The largest computer system so far installed for hospital work in London – an ICL 1905E – has come into service at Kings College Hospital, where the UK’s first attempt will be made at using the computing on-line to wards and departments. The KCH project is the first of the Department of Health’s experimental large-scale computer schemes, which were formally announced at the beginning of this year. Basically, it will be a system for retrieval of medical records by which patient information will be input and accessed through visual display units. These are of the ‘local’ type, installed not more than 2,000 feet from the computer, which give the user the fastest possible response time. (CW143 p3) PDP-8/L Processors in Newspaper Offices: Computerised typesetting systems using PDP-8/L central processors have been installed in three newspaper offices. DEC now has 23 systems based on PDP-8 computers installed In the UK but these are the first to use the PDP-8/L. At the Belfast Telegraph, a dual system has been installed, with photoelectric readers and punches sited in the perforating and composing rooms. Unjustified tapes can be produced at a continuous 110 cps, or 12,000 newspaper lines per hour. (CW144 p8) New Company to meet Maintenance Needs: A new UK company, Computer Field Maintenance Ltd, has been formed to undertake the maintenance of proven computer systems. The company has as its managing director Mr Derek Royle, who was responsible for the development and management of English Electric Computer’s installation and field engineering organisation until it was incorporated into ICL in 1968. (CW145 p20) OCR Attachments for ICL Readers: The first document readers from ICL to have OCR attachments have passed their site trials and will come into operation later this year at the Department of Health and Social Security, Newcastle-upon-Tyne. They will be used to read in a total of 50 million Giro payment orders per hour into an ICL 1901. Three type 8201 document readers will be used. (CW146 p24) Remote terminals test radio link: The first elements of a unique telecommunications network, using radio links between CRT displays and a central computer, are now being installed in offices and showrooms of the West Midlands Gas Board. When complete, the network will provide an on-line customer inquiry service. It will be based on an ICL 1907 computer at the board’s head office at Solihull, and will use ICL 7152 inquiry terminals. (CW148 p24) The Moon Machines: While landing a man on the moon is a testament to man’s courage and endurance, the electronic and mechanical systems on board Apollo 11, together with the spaceship’s earthbound computer accoutrements, are evidence of his incredible ingenuity. Throughout the mission to the moon the world’s attention has been focused almost exclusively on the adventures of the three astronauts, Armstrong, Collins and Aldrin. Now, as Computer Weekly goes to press, the Apollo men are preparing for their return to earth with complete success within their grasp and the rest of the enormous organisation that made the journey possible begins to unwind. (CW149 p12) Simulating the Great Adventure: When Eagle settled and Armstrong and Aldrin set foot on the moon early last Monday morning, they fulfilled one half of President Kennedy’s proclamation in 1961, that the USA would land men successfully on the moon and return them safely to the earth in this decade. The return of the Apollo 11 will complete this objective. The Apollo programme has proven, among other things, that a spacecraft can be designed and flown through the use of computers and simulation techniques prior to the flight test stage. In this case, the flight test stage and the actual flight are synonymous. The Apollo project presented to NASA a unique problem to design a spacecraft to fly, land and take-off in an environment unknown on Earth. (CW149 p12) Space Power: Some idea of the computing power assembled for the task of getting man to the moon can be gathered from this listing of systems used and their locations and applications. At the Manned Spacecraft Center the Real Time Computer Complex uses two IBM 360/75s for interpreting radar and flight data and for computing flight path. Network switching is handled by a Univac 494 complex which controls communication lines into Houston. For the Goddard Real Time System at the Goddard Space Flight Center two 360/75s check tracking station operations and incoming data. Here too, Univac 494s are used for network switching, controlling worldwide communications from tracking stations and ships. Offline analysis of communications network data is done on an IBM 360/95. In space the Saturn instrument unit uses an IBM computer for guidance, navigation and control of launch vehicle, while the command module and lunar module have MIT/Raytheon computers for navigation and for lunar and abort guidance systems. Tracking at 17 ground stations and on four ships is handled by Univac 642Bs and Univac 1218 and 1230 computers controlling equipment and data flow. At Kennedy Space Center, Saturn testing was done with the aid of RCA 110As operated by IBM to check-out the launch vehicle’s three stages. Testing of the command and lunar modules was done on CDC 160Gs and countdown processing was the task of GE 635s. At Patrick Air Force Base range safety was under the control of CDC 3600s and special communication aircraft used data from an IBM 360/50. Hundreds of installations were used in the programme. These included 360/75s at MIT Instrumentation Laboratory where programs were tested before being wired into spacecraft computer memories; Model 91s at Goddard and in New York handle engineering calculations and a 360/75 at Houston was used as the ground support simulation computer. There is also a 360/50 at Houston which is being used to validate data being transmitted from instruments left on the moon by the Apollo 11 crew. Throughout the world at major locations, at tracking sites and on board the tracking ships, there were a total of 101 Univac systems in use. These included 48 642Bs, 33 1218s, six 494s, seven 1108s, and seven 418s. (CW149 p21) Point-of-sale Terminal ready for Decimalisation: The compact point-of-sale terminal developed by English Numbering Machines Ltd under contract to the GPO’s National Data Processing Service is now expected to go into production early next year and will be available for installation ready for decimalisation in February, 1971. (CW150 p28) NPL Orders Interface Units from Honeywell: The latest company to join the growing number of those making British Standard Interfaces is the Computer Control Division of Honeywell. It has received an order for four such units from the NPL where much of the original development work on the interface was carried out. The units will be used to extend the input-output facilities of four Honeywell DDP 516 computers currently in use at the laboratory. Three of these are being used in the Computer Science Division in the development of communications networks and pattern processing related to character recognition. (CW151 p1) System 4s get new Mag Tape Units: New magnetic tape units for the System 4 range of computers include three new nine-track phase encoded systems and a standard seven-track unit to ensure complete industry compatibility. The nine-track tapes will be compatible with both current and proposed ISO and ECMA standards. (CW154 p32) |

Contact details

Readers wishing to contact the Editor may do so by email to

Members who move house or change email address should go to

Queries about all other CCS matters should be addressed to the Secretary, Rachel Burnett at rb@burnett.uk.net, or by post to 80 Broom Park, Teddington, TW11 9RR. |

Forthcoming EventsLondon Seminar Programme

London meetings take place at the new BCS location – 25 Copthall Avenue Moorgate EC2R 7BP starting at 14:30. The venue is on the corner of Copthall Avenue and London Wall, a three minute walk from Moorgate Station and five from Bank. You are strongly advised to use the BCS event booking service to reserve a place at CCS London seminars. Web links can be found at www.computerconservationsociety.org/lecture.htm . For queries about London meetings please contact Roger Johnson at r.johnson@bcs.org.uk. Manchester Seminar Programme

North West Group meetings take place take place at Manchester Metropolitan University: 17:00 for 17:30. For queries about Manchester meetings please contact Alan Pickwick at alan_c_pickwick@btinternet.com Details are subject to change. Members wishing to attend any meeting are advised to check the events page on the Society website at www.computerconservationsociety.org/lecture.htm. MuseumsSIM : Demonstrations of the replica Small-Scale Experimental Machine at the Science and Industry Musuem in Manchester are run every Tuesday, Wednesday, Thursday and Sunday between 12:00 and 14:00. Admission is free. See www.scienceandindustrymuseum.org.uk for more details. Bletchley Park : daily. Exhibition of wartime code-breaking equipment and procedures, plus tours of the wartime buildings. Go to www.bletchleypark.org.uk to check details of times, admission charges and special events. The National Museum of Computing Colossus Galleries open daily 10.30-17.00; full Museum open Tuesday — Sunday 12.00-17.00. Situated on the Bletchley Park campus, TNMoC covers the development of computing from the “rebuilt” Turing Bombe and Colossus codebreaking machines via the Harwell Dekatron (the world’s oldest working computer) to the present day. From ICL mainframes to hand-held computers. Please note that TNMoC is independent of Bletchley Park Trust and there is a separate admission charge. Visitors do not need to visit Bletchley Park Trust to visit TNMoC. See www.tnmoc.org for more details. Science Museum : There is an excellent display of computing and mathematics machines on the second floor. The Information Age gallery explores “Six Networks which Changed the World” and includes a CDC 6600 computer and its Russian equivalent, the BESM-6 as well as Pilot ACE, arguably the world’s third oldest surviving computer. The Mathematics Gallery has the Elliott 401 and the Julius Totalisator, both of which were the subject of CCS projects in years past, and much else besides. Other galleries include displays of ICT card-sorters and Cray supercomputers. Admission is free. See www.sciencemuseum.org.uk for more details. Other Museums : At www.computerconservationsociety.org/museums.htm can be found brief descriptions of various UK computing museums which may be of interest to members. |

North West Group contact details

|

||||||||||||

Committee of the Society

|

Computer Conservation SocietyAims and objectivesThe Computer Conservation Society (CCS) is a co-operative venture between BCS, The Chartered Institute for IT; the Science Museum of London; and the Museum of Science and Industry (MSI) in Manchester. The CCS was constituted in September 1989 as a Specialist Group of the British Computer Society (BCS). It thus is covered by the Royal Charter and charitable status of BCS. The aims of the CCS are to

Membership is open to anyone interested in computer conservation and the history of computing. The CCS is funded and supported by voluntary subscriptions from members, a grant from BCS, fees from corporate membership, donations, and by the free use of the facilities of our founding museums. Some charges may be made for publications and attendance at seminars and conferences. There are a number of active Projects on specific computer restorations and early computer technologies and software. Younger people are especially encouraged to take part in order to achieve skills transfer. The CCS also enjoys a close relationship with the National Museum of Computing.

|